Programmable Logic Controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential/position control, timed counting and input/output control are widely applied to the field of industrial automation control. Delta’s DVP series programmable logic controllers offer high-speed, stable and highly reliable applications in all kinds of industrial automation machines.

Applications

HVAC, molding injection machine, big storage management, packaging machine,

precise textile machine, logistic system

Features:

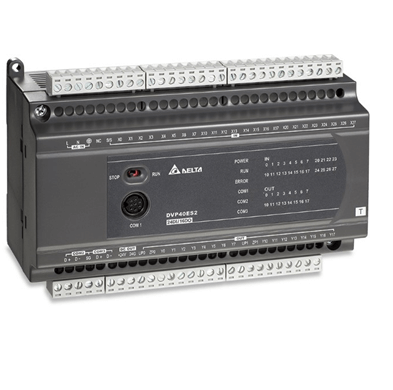

Applications

HVAC, molding injection machine, big storage management, packaging machine,

precise textile machine, logistic system

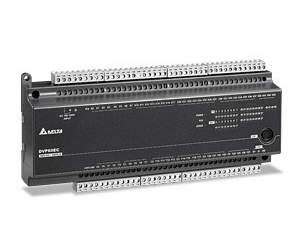

Features:

Applications

Processing machines, injection molding machines, packaging machines, precision textile machines, large-scale warehousing, logistics systems

Specifications:

Applications

Single control unit, landscape fountain, building automation

Specifications:

Applications

HVAC, printing machine, packaging machine, molding injection machine, inspection system

Specifications:

Applications:

Automated equipment such as electronics manufacturing, labeling, food packaging, and textile machines

Specifications:

Applications:

Electronics manufacturing, packaging, printing, sealing, wire electrical-discharge machining, pharmaceutical machines, digital board cutting machines, CNC lathe, and more.

Specifications:

Copyright © 2023 United Control Engineers India PVT LTD | Developed By Bhanu Pratap Singh