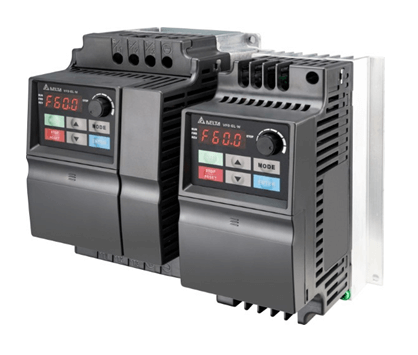

Delta’s AC Drives are able to efficiently control motor speed, improve machine automation and save energy. Taking advantage of our strong position in power electronics technology, Delta’s VFD Series of AC motor Drives has evolved rapidly. Each Drive series is designed to meet specific application needs. Our AC Drives accurately control speed and torque, smoothly handle an increased load, and provide numerous custom control and configuration operating modes.

Applications

Features:

Range: Single Phase – 0.025HP to 3HP

Range: Three Phase – 1HP to 5HP

Applications

Small size pump & fan, blowing machine, conveyer belt, simple DIY processing equipment

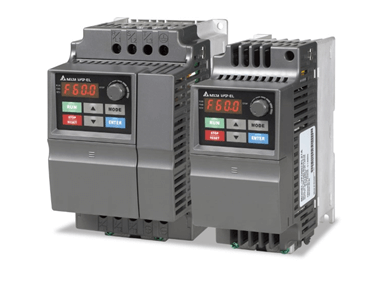

Features:

Range: Single Phase – 0.025HP to 3HP

Range: Three Phase – 0.5HP to 5HP

Applications

Machine tools, textile machines, woodworking machines, packaging machines, electronics, fans, pumps, air compressors

Features:

Range: Single Phase – 0.5HP to 3HP

Range: Three Phase – 0.5HP to 30HP

Applications

Fans & pumps, conveyors, blowing machines, packing machines, wood working machines

Features:

Range: Single Phase – 0.5HP to 3HP

Range: Three Phase – 0.5HP to 10HP

Applications

Smaller cranes; washing machines; treadmilsl; robot arm of injection machine (clamp); elevator; grinding machine; drilling machine; wood machine; webbing loom; air conditioner for large buildings; water supply system for large buildings, etc.

Features:

Range: Single Phase – 0.25HP to 3HP

Range: Three Phase – 0.5HP to 30HP

Applications

Extruders, rubber millers, injection molding machines, pipe bending machines, conveyance systems, winding machines, bridge cranes, stage lifting systems, glass tempering furnaces, electromagnetic stirrers

Features:

Range: Three Phase – 1HP to 425HP

Applications

Fixed-displacement pumps (fix flow and fix time), building automation, factory automation, HVAC drives, cooling pumps, cooling towers and general motor applications.

Features:

Range: Three Phase – 30HP to 100HP

Copyright © 2023 United Control Engineers India PVT LTD | Developed By Bhanu Pratap Singh