Top 10 Industrial Automation Trends to Know in 2024

Introduction of Industrial Automation Trends

In 2024, industrial automation trends are set to transform and redefine how businesses operate in a rapidly evolving landscape. As technology advances, AI integration becomes crucial, bringing a new era of efficiency and innovation in various industries. From digital twins’ revolutionary concept to the seamless connectivity of IoT, technology is transforming industries significantly. Impactful role of 5G technology and businesses are on the cusp of a paradigm shift. So, join us on this exploration of the cutting-edge developments. where human-machine collaboration, energy-efficient automation, and cybersecurity solutions converge to create a landscape of unprecedented possibilities. Embrace future with insights into these trends, discover how businesses can thrive by staying ahead in realm of industrial automation.

1.User AI-Driven Process Discovery

AI-driven process discovery is cutting-edge approach that leverages Artificial Intelligence to unveil and analyze intricate business processes within organization. This innovative method employs machine learning algorithms to sift through large datasets, identifying patterns and deviations in how tasks executed. By automating the process discovery phase and AI not only accelerates the understanding of workflows but also provides unparalleled precision. This transformative technology empowers businesses to streamline processes, and enhance operational efficiency, and make data-driven decisions for continuous improvement. Process discovery offers organizations a dynamic tool to optimize workflows, providing unprecedented ease and insight for innovation. This is most important Industrial Automation Trends.

2.Democratization of Automation

The democratization of automation refers to the widespread accessibility and adoption of automated processes, making advanced technologies available to a broader audience. Furthermore, automation is not limited to large corporations but is made accessible to businesses of all sizes and industries. This movement is driven by the development of user-friendly tools, intuitive platforms, and simplified interfaces that enable individuals with varying technical backgrounds to implement automation solutions. Consequently, it empowers organizations to enhance efficiency, reduce costs, improve productivity, and fosters a more inclusive and innovative business environment. This shift marks a departure from exclusive and complex systems to an era where automation becomes a tool for widespread empowerment and efficiency across diverse sectors.

3.Hyperautomation in Customer Service

4.Hyperautomation for Cybersecurity

5.Integration of IoT and Hyperautomation

The integration of Internet of Things and hyperautomation signifies powerful convergence of technologies aimed at revolutionizing efficiency, connectivity in various industries. This synergy combines seamless communication of IoT devices with intelligent automation capabilities of hyperautomation, creating dynamic ecosystem where devices processes work harmoniously. IoT sensors generate real-time data, feeding into hyperautomation systems that analyze, automate, and optimize workflows. This integration not only enhances operational efficiency by automating routine tasks but also enables businesses to make data-driven decisions promptly. The result is sophisticated network where physical, digital realms converge, offering unparalleled insights, responsiveness, and productivity across diverse sectors.

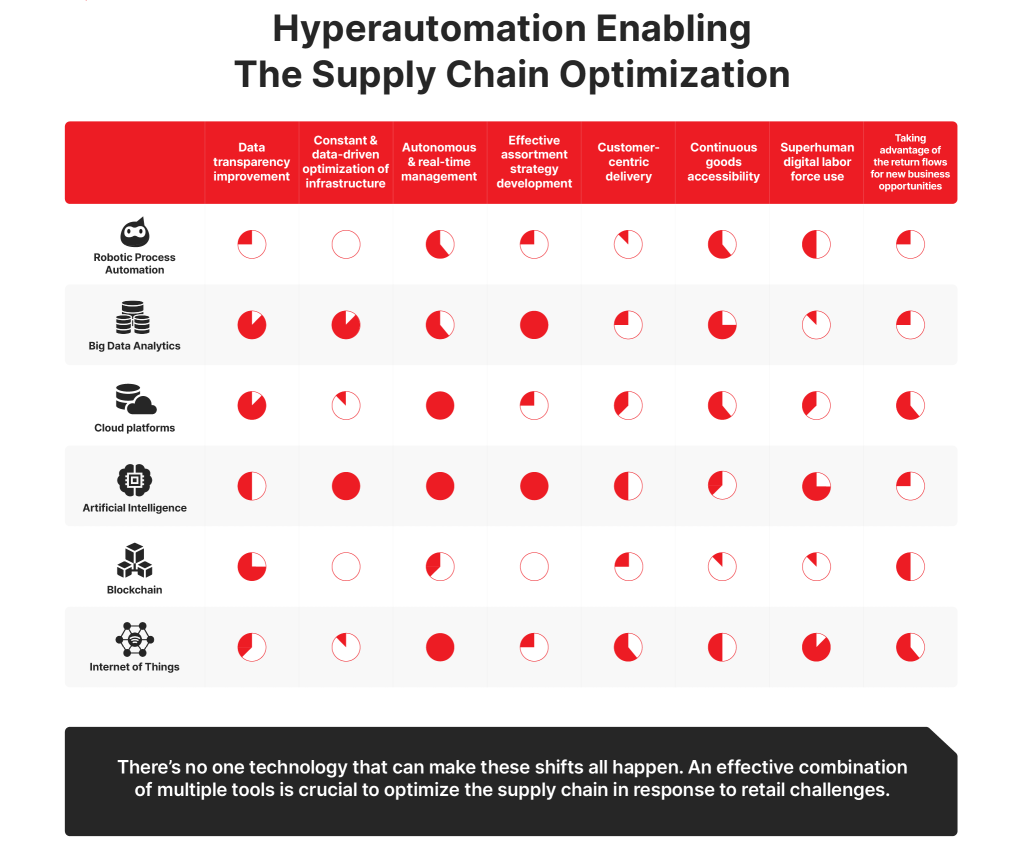

6.Hyperautomation for Supply Chain Management

Hyperautomation supply chain management is transformative strategy that leverages advanced technologies, including Artificial Intelligence, machine learning, (RPA), to revolutionize optimize entire supply chain. This approach integrates intelligent automation into key supply chain, such as inventory management, demand forecasting, logistics, streamlining operations and improving overall efficiency. Automating routine tasks, analyzing vast datasets for insights, enhancing decision-making processes, hyperautomation ensures more agile, responsive, resilient supply chain. This innovative solution empowers organizations to adapt to dynamic market demands, reduce costs, enhance end-to-end visibility of their supply chain, ultimately driving competitive advantage in today’s fast-paced business landscape.

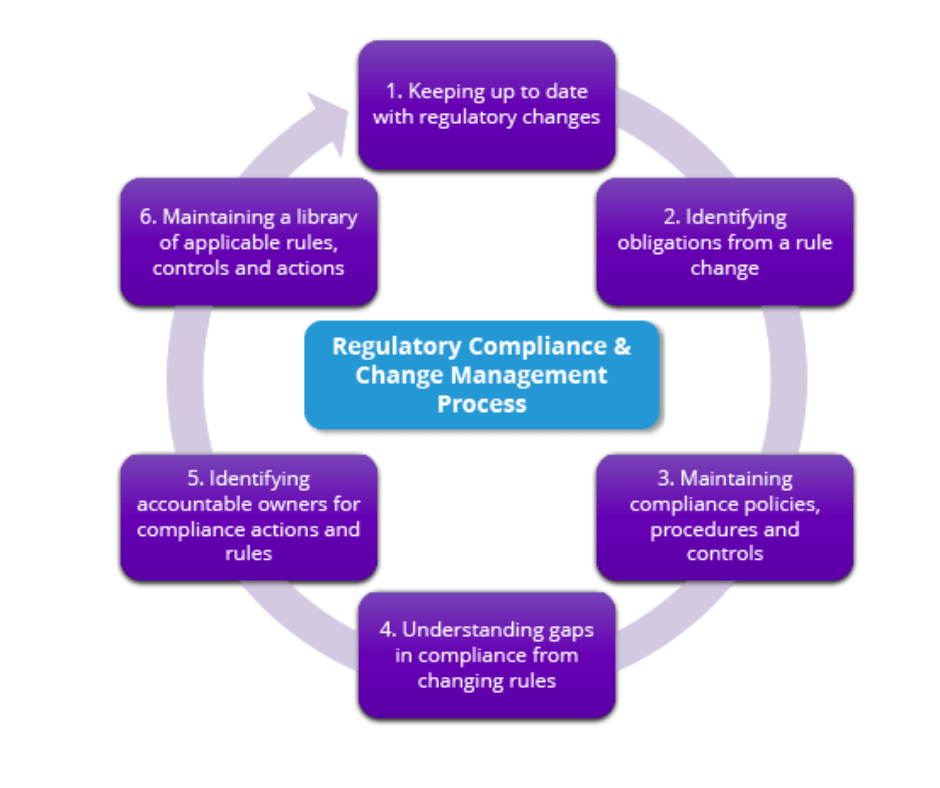

7.Hyperautomation for Compliance and Regulatory Reporting

Harnesses the power of advanced technologies such as Artificial Intelligence robotic process automation to streamline and enhance regulatory compliance processes. This approach automates the complex tasks associated with compliance management, ensuring accuracy, consistency, and efficiency in meeting regulatory requirements. Utilizing intelligent algorithms, machine learning, hyperautomation enables organizations to navigate intricate regulatory landscapes, reduce manual errors, and promptly adapt to evolving compliance standards. This transformative solution not only improves the accuracy of regulatory reporting but also frees up valuable resources, allowing businesses to focus on strategic initiatives while maintaining a robust and compliant framework.

8.Hyperautomation in Healthcare

Amalgamates advanced technologies like Artificial Intelligence, machine learning, and (RPA) to transform elevate healthcare industry. This approach automates routine tasks, enhances operational efficiency, and improves patient care by integrating intelligent automation into various processes, from administrative tasks to patient diagnosis and treatment planning. leveraging sophisticated algorithms automation tools, hyperautomation in healthcare not only streamlines workflows but also contributes to more accurate diagnostics, personalized treatment plans, efficient healthcare delivery. This innovative solution empowers healthcare providers to enhance overall patient experience, optimize resource utilization, stay at forefront of advancements in medical care.

9.Sustainable Hyperautomation

Combines advanced technologies, such as Artificial Intelligence, machine learning, and (RPA), with focus on environmental social responsibility. This strategy aims to optimize processes, enhance efficiency, and reduce environmental impact by integrating sustainable practices into automation workflows. From energy-efficient algorithms to eco-friendly resource management, sustainable hyperautomation not only improves operational effectiveness but also aligns with global efforts towards sustainability. This forward-thinking approach enables organizations to achieve balance between technological innovation and environmental stewardship, contributing to more sustainable and responsible future.

10.Continuous Learning and Adaptation

Continuous learning and adaptation represent a dynamic approach that underscores the ongoing evolution and improvement of processes. In various contexts, such as technology or business strategies, this concept involves a commitment to constant learning, refining strategies based on insights gained, and adapting to changing circumstances. Whether applied in development, technology deployment, emphasis on continuous learning, staying at forefront of advancements in rapidly changing landscape. This approach fosters agility, enabling individuals organizations to thrive in dynamic environments by embracing mindset of perpetual growth improvement.

5 Rising In Industrial Automation Trends in 2024.

1. Labor challenges will continue to impact businesses:-

One crucial strategy to address labor challenges is the integration of robotization alongside the being pool. By automating homemade, repetitious, and dangerous tasks, businesses can shield their product lines from the impact of high development rates.

For a successful transition, manufacturers are encouraged to apply robotization results with a low hedge to entry. This approach ensures that workers without advanced specialized robotization chops can readily borrow and acclimatize to this transformative technology. With robotization humans working alongside each other, manufacturers aren’t as vulnerable to ongoing labor challenges can successfully boost product effectiveness key to thriving in face of evolving dynamics in manufacturing pool.

2. Automation will become a necessity, not just a “nice to have”:-

Over the once three decades, the artificial robotization assiduity has experienced a gradational elaboration. With complex, heritage technology and large capital investments, artificial robotization was created and priced for high- outturn manufacturing. moment, recent forces, similar as the labor deficit and the COVID- 19 epidemic. Have increased the demand for robotization, performing in rapid-fire elaboration in the availability of robotization technology. As robotization continues to advance, there’s a notable shift in its social perception. Contrary to belief that robotization displaces jobs, it’s getting decreasingly apparent that , infact, creating further employment openings. In Future of Jobs report, it was set up 97 million new places may crop as result of espousing robotization.

In 2024, robotization will come a necessary part of product lines for manufacturers.

3. Speed will emerge as a top priority:-

In 2024, speed to robotization is poised to come pivotal differentiator as further manufacturers admit necessity of robotization technology. According to exploration from Assembly Magazine, increased demand for robotization has surged supereminent times within the last many times.

numerous diligence, especially those characterized by shorter product lifecycles, have honored speed from design to operation as pivotal staying ahead. Assembly reports that “ 82 of masterminds rank delivery time as an important factor when opting factors for an robotization design.

These results come as no surprise. The process of enforcing traditional robotization technologies, from inauguration to completion, can stretch over a time. This extended timeline is result of intricate nature technology, involvement of multiple merchandisers, and growing frequence of long lead times.

4. Do-it-yourself automation and the creation of Advanced Manufacturing Teams will rise:-

“ DIY ” robotization is practice of singly designing, enforcing artificial robotization systems by exercising draw- and- play tackle and software factors. With ongoing inventions in artificial robotization assiduity that make robotization more accessible,DIY approach is gaining traction is anticipated to continue thriving in 2024.

Within Manufacturing robotization Platform, small- sized businesses crop as primary adopters, showcasing growing frequence of DIY robotization in this sector. specially, manufacturers with smaller than 200 workers were preliminarily hindered by the complexity and cost of robotization technologies. Now, they aren’t only embracing automated results at the loftiest rates but also realizing the value of inflexibility and customization.

5. Artificial Intelligence will enable faster and more efficient processes:-

In the forthcoming time, one of overarching trends set to shape colorful business sectors is integration of ( AI). In environment of artificial robotization manufacturing, our prognostications point towards a nuanced elaboration of AI, unfolding across three distinct orders.

Firstly:

We anticipate the emergence of the “ Industrial Copilot. ” This conception, frequently likened to “ ChatGPT ” of programming, blends mortal- machine collaboration to enhance effectiveness and effectiveness in artificial processes.

The Second Category:

Autonomous Robots, is a growing trend where robots can be programmed with little to no mortal intervention. This shift from stir- grounded robotics, where programmers explicitly define robot stir. To charge- grounded robotics allows robots to understand process constraints can perceive acclimatize to their terrain to complete complex operations.

The Third Category:

Machine literacy, takes the conception of AI further by enabling robots to learn and ameliorate from experience. The eventuality of machine literacy is measureless and can greatly ameliorate manufacturing quality examination, personalization, and more.

Industrial Automation Trends in News with Data

1. Labor Challenges and Automation

- Data: The retirement of Baby Boomers is causing significant labor shortages. By 2030, it’s predicted there will be 2.1 million unfilled jobs in the manufacturing sector.

- News: As a result, automation is being adopted to address this shortage, allowing existing workers to transition to more skilled roles.

2. Necessity of Automation

- Data: With increased production demands and labor shortages, automation has become essential rather than optional.

- News: Consequently, companies are investing heavily in automation to enhance production efficiency and create jobs by shifting human roles to higher-skilled tasks.

3. Generative AI and Digital Twins

- Data: Generative AI and digital twin technology are providing faster product iterations, improved quality, and enhanced employee training.

- News: Therefore, these technologies are expected to drive significant innovation and efficiency in manufacturing processes.

4. 4D Vision Technology

- Data: Advanced vision technology, particularly 4D vision, is improving the speed and accuracy of automated applications.

- News: This improvement is making industrial processes faster and safer.

5. Expansion of AGVs and AMRs

- Data: Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are being used beyond warehouses in broader industrial applications.

- News: Furthermore, their integration with collaborative robots (cobots) is creating more versatile and efficient operations.

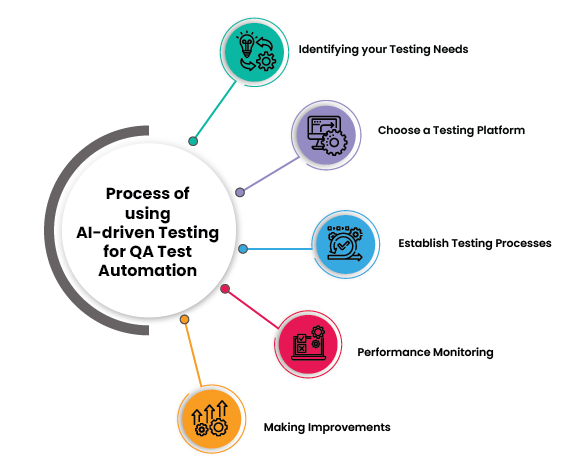

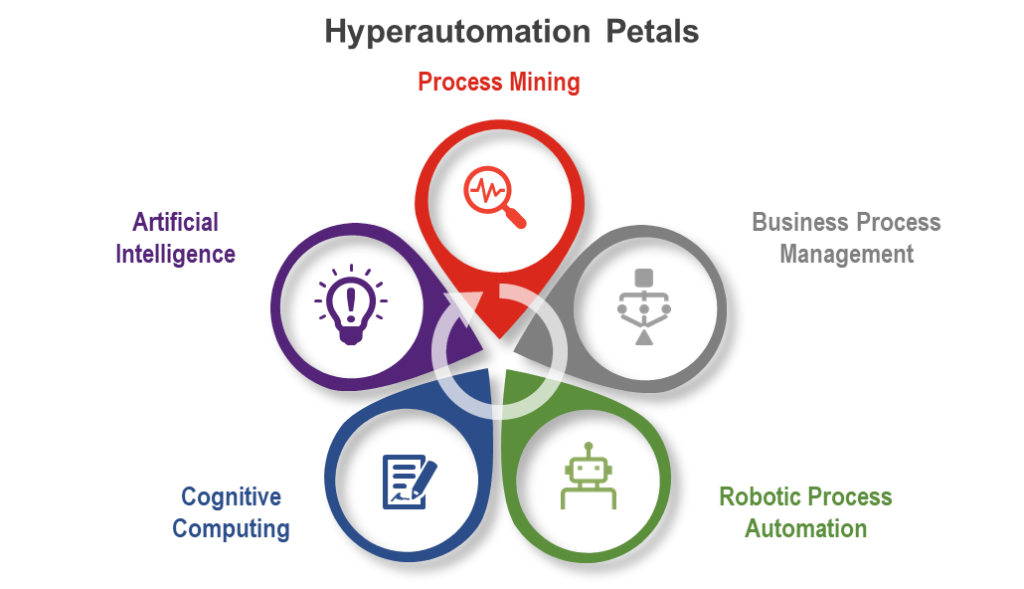

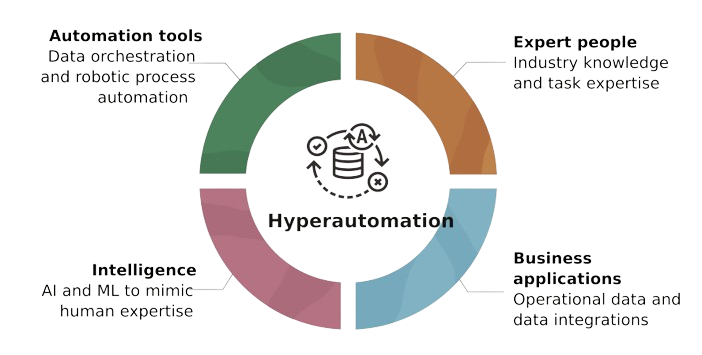

6. Hyperautomation

- Data: Hyperautomation involves integrating technologies like AI, robotic process automation, and intelligent process automation.

- News: As a result, this approach optimizes end-to-end processes and automates decision-making, significantly boosting productivity and agility.

7. Edge Computing

- Data: Edge computing processes data closer to its source, reducing latency and enhancing security.

- News: Thus, it is crucial for real-time automation applications in smart cities, IoT networks, and industrial plants.

8. Ethical Automation

- Data: Emphasis on ethical considerations, including data privacy and mitigating algorithmic biases, is growing.

- News: Consequently, ethical automation ensures fair and accountable decision-making.

9. Speed to Automation

- Data: Rapid adoption of automation technologies will be a key competitive differentiator.

- News: Therefore, companies that can quickly implement these technologies will gain a significant edge.

10. Adoption of Digital Technologies

- Data: Increased investments in digital twins, generative AI, and 4D vision technologies are expected.

- News: As a result, these investments are aimed at achieving greater efficiencies and innovation in manufacturing.

Conclusion

In conclusion, the future of industrial automation in 2024 promises unprecedented advancements. Businesses that embrace these trends stand to benefit from increased efficiency, cost reduction, and improved safety measures. Staying informed and adapting to these changes is key for sustained success in the rapidly evolving landscape of industrial automation.