Introduction

In the vibrant city of Greater Noida, industrial automation has become a driving force. Secondly, reshaping the way businesses operate and enhancing efficiency across various sectors. Furthermore, this article explores the evolution, applications, challenges, and future trends of industrial automation in Greater Noida.

Moreover, in the heart of India, Greater Noida and Delhi NCR, a booming city known for its industrial prowess, has witnessed a remarkable transformation with the advent of industrial automation. Automation describes a wide range of technologies that reduce human intervention in processes. This is mainly done by predetermining decision criteria, subprocess relationships, and related actions. Additionally, as well as embodying those predeterminations in machines.

Table of Contents

Evolution of Industrial Automation

Historical Overview

Industrial automation traces its roots back to the mechanization of production processes during the Industrial Revolution. Over time, it has evolved from basic machinery to sophisticated systems that integrate cutting-edge technologies.Industry 4.0, often referred to as the fourth industrial revolution, encapsulates this era of smart manufacturing. Furthermore, it integrates cyber-physical systems and cloud computing into industrial processes.

Additionally, the use of artificial intelligence and machine learning further refined automation capabilities, allowing systems to adapt and learn from data patterns.

Technological Advancements

Additionally, advancements in robotics, the Internet of Things (IoT), and artificial intelligence have played a pivotal role in shaping the landscape of industrial automation. These technologies enhance productivity, accuracy, and overall efficiency. Furthermore, Artificial Intelligence and Machine Learning technologies have empowered automation systems to learn, adapt, and optimize processes, contributing to increased efficiency and error reduction. Together, these technological strides collectively define the contemporary landscape of industrial automation, paving the way for smart, interconnected, and adaptive manufacturing environments.

Key Technologies in Industrial Automation

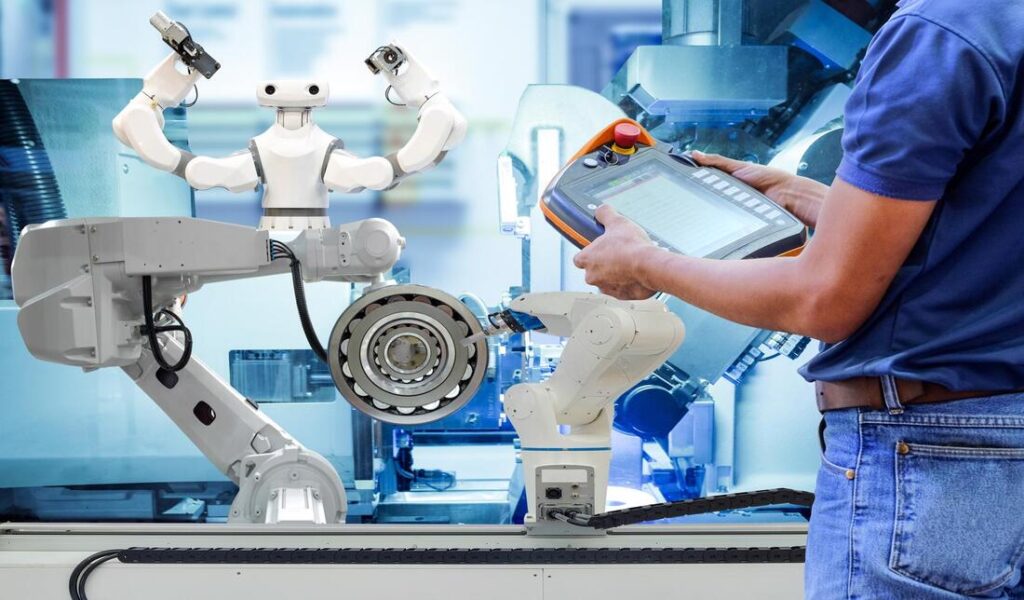

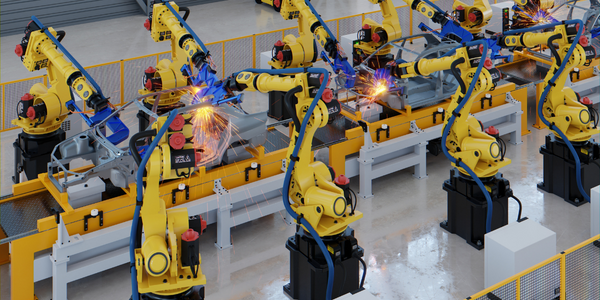

Robotics and Automation:- Additionally, in the Greater Noida and Delhi NCR industrial sector, robots have revolutionized manufacturing processes. Consequently, robots are now an integral part of assembly lines, performing tasks with precision and speed. Furthermore, advances in robotic manipulation, such as more sophisticated arms and end-effectors, have improved precision in tasks like assembly and handling.

Additionally, digital twins, creating virtual replicas of physical systems, facilitate simulation and optimization before implementation, reducing risks and improving performance. In conjunction, automation software, including Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems, provides real-time control and centralized monitoring. Furthermore, Additive Manufacturing, such as 3D printing, contributes to agile production through rapid prototyping and customization. Moreover, Augmented Reality (AR) and Virtual Reality (VR) technologies find application in training and maintenance, offering immersive solutions.

IoT Integration:- The seamless integration of IoT devices has enabled real-time monitoring and control of industrial machinery. This connectivity optimizes resource utilization and facilitates predictive maintenance.The deployment of sensors captures vital information, such as temperature, pressure, and production metrics, providing valuable insights for optimizing efficiency and decision-making. By harnessing the power of IoT, industries can create agile, responsive ecosystems that contribute to intelligent, data-driven decision-making and streamlined automation processes.

Artificial Intelligence in Manufacturing:- Artificial intelligence (AI) applications, such as machine learning algorithms, contribute to predictive analytics, quality control, and process optimization, making manufacturing in Greater Noida more intelligent and adaptive.AI-driven robotics and automation systems exhibit adaptive capabilities, learning from patterns and continuously refining their performance.AI in manufacturing stands as a key technological pillar, driving innovation and efficiency in modern industrial settings.

Industrial Automation Applications in Greater Noida

Manufacturing Sector:- Greater Noida’s and Delhi NCR manufacturing sector has witnessed a revolution with automated production lines.Reducing manual intervention, minimizing errors, and increasing production output.

Automotive Industry:- In the automotive hub of Greater Noida and Delhi NCR, automation has led to innovations in production techniques.Resulting in high-quality vehicles and enhanced competitiveness in the global market.

Energy and Power Plants:- Automation has improved the efficiency and safety of energy and power plants in Greater Noida and Delhi NCR, ensuring a stable and reliable energy supply.

Advantages of Implementing Industrial Automation

1.Increased Efficiency

Automation increased efficiency by accelerating production cycles, reducing downtime, and optimizing resource allocation, leading to increased overall output.

2.Cost Reduction

The implementation of Industrial automation in Greater Noida And Delhi NCR has contributed to cost reduction. And improved resource utilization, minimized waste, and enhanced energy efficiency.

3.Enhanced Safety Measures

Automated processes in industries ensure a safer working environment by minimizing human exposure to hazardous conditions, leading to a decline in workplace accidents.

Trend Industrial Automation in Greater Noida & Delhi NCR

The integration of 5G technology will enhance the speed and reliability of communication between automated systems.Paving the way for more advanced and interconnected industrial processes in Greater Noida and Delhi NCR. With the capacity to handle a massive number of connected devices simultaneously, 5G facilitates the seamless communication of sensors, machines, and control systems.The incorporation of 5G in industrial automation marks a significant leap forward, promising more agile, connected, and responsive manufacturing ecosystems.

Greater Noida is poised to adopt sustainable automation practices, focusing on eco-friendly technologies and resource-efficient processes to minimize environmental impact.the implementation of energy-efficient technologies, such as advanced sensors and control systems, to minimize energy consumption during manufacturing processes.This shift towards sustainable automation not only aligns with global environmental goals but also enhances operational efficiency and resilience in the face of evolving ecological challenges.

The future of industrial automation involves greater collaboration between humans and machines. Human skills complemented by automation will result in more sophisticated and efficient operations.Advanced interfaces, such as augmented reality and intuitive control systems, facilitate seamless communication between humans and machines. This trend not only improves efficiency but also promotes a safer and more ergonomic working environment.

Impact on Employment Landscape

- Job Creation in Tech and Engineering Roles:

- Shift in Job Roles towards Specialization

- Growing Need for Digital Skills

- Emergence of New Job Categories

- Increased Emphasis on Soft Skills

- Investment in Training and Reskilling

- Concerns about Job Displacement

- Collaborative Work Environments

- Job Opportunities in Maintenance and Support

- Evolving Entrepreneurial Opportunities

Recommendations for Businesses

- Adopt Industry 4.0 Technologies

- Invest in Workforce Development

- Explore 5G Integration

- Enhance Cybersecurity Measures

- Foster Human-Machine Collaboration

- Implement Predictive Maintenance

- Leverage Augmented Reality (AR)

- Encourage Continuous Innovation

- Collaborate with Industry Partners

- Focus on Flexibility and Adaptability

How to increase the Industrial Automation in Greater Noida & Delhi NCR?

To increase industrial automation in Greater Noida and Delhi NCR, Faridabad a strategic approach is essential. Firstly, businesses need to embrace key technologies such as IoT, AI, robotics, and data analytics. These innovations enhance efficiency and productivity. Overcoming challenges, including resistance to change and initial investment concerns, requires awareness campaigns and government support. Collaborative efforts, industry partnerships, and knowledge-sharing platforms play a vital role in creating a conducive environment. Moreover, investing in a skilled workforce through training programs is crucial. Highlighting success stories and real-world case studies can inspire businesses to adopt automation, fostering economic growth and sustainability in the region.

Conclusion

Industrial automation has become a transformative force in Greater Noida, redefining the way industries operate and setting the stage for future growth. As the city embraces advanced technologies, there is a promising outlook for increased efficiency, sustainability, and collaboration between humans and machines.The landscape of industrial automation in Greater Noida reflects a dynamic and evolving ecosystem.As Greater Noida continues to position itself as a hub for industrial growth, the ongoing integration of these technologies promises not only increased productivity and operational efficiency but also sets the stage for a more interconnected, intelligent, and sustainable future in industrial automation.